Materializing Ideas

The LEHVOSS Compounds division supports designers, design engineers and component manufacturers in defining the most suitable plastic for their component and thus in developing more powerful components with lower system costs. Customers benefit from our well-founded knowledge of materials and applications, the independent selection of raw materials and the decades of experience of the LEHVOSS engineers. The basis for this was laid by the LEHVOSS Group back in the 1910s as the world market leader for casein.

We have been developing, producing, testing and marketing thermoplastic compounds since the 1970s, always in close cooperation with our customers. We have developed many high-performance materials that have never been matched before. For example, extremely wear-resistant tribological compounds and carbon fiber compounds with maximum strength and rigidity and high toughness at the same time. The materials are of course optimized for the respective processing technologies, such as injection molding, extrusion, 3D printing or powder coating.

Our products with the brand names LUVOCOM®, LUVOCOM® P, LUVOTECH®, LUVOCOM® 3F and LUVOSINT® stand for quality and reliability worldwide. Products with the suffix eco, e.g. LUVOTECH® eco, are sustainable and based on recycled polymers. The carbon footprint is significantly reduced.

Our service portfolio

Global material development, production and availability

Solution provider and high level of expertise for demanding applications

Extensive service:

Material data

Lab and Innovation Center

Application Engineering Support

Innovation and market leader in carbon fiber reinforced, tribological, high temperature resistant, conductive and 3D printing compounds

Recognized development partner of OEMs, system suppliers and processors

Material Selection and Data Sheets

Global presence

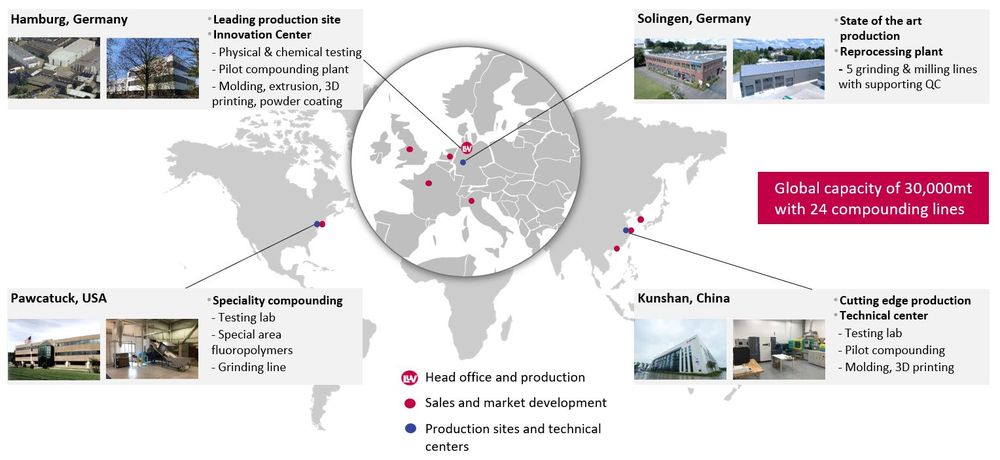

We are represented around the world. To help us react better to individual client and market requirements as well as to shorten supply routes and processing times, we produce on three continents. Apart from at our German plants in Hamburg and Solingen, we also produce in the USA and China (Video about the move and expansion of the plant in the year 2023). Our local market development staff will be happy to provide on-site support for your project.