Materials solutions for the automotive industry

Travelling safely

As a driver of technological innovation, the automotive industry makes high demands of new materials and their quality. In almost all of the systems in today’s automobiles, compounds increase the performance of components or help to reduce weight and save fuel. Thanks to decades of experience with materials for functional parts and components, we are able to support you with advice in all issues of material selection. Consequently, using high-temperature resistant, high-strength and tribologically optimized compounds, we are able to produce components in plastic for very heavy-duty use. We have reference clients for all relevant assemblies and support you from development through to series production.

New generation of suspension strut bearings

The advancing architectural change being experienced by the automobile is leading to a necessity for substantial changes, which also affect the materials used to date. Many vehicle systems are currently being called into question. Suspension systems, which belong to the vehicle exterior segment, will, however, also be retained as electromobility ..more

High-temperature resistant – in great demand

Through the use of high-temperature resistant polymers and with the addition of suitable reinforcing materials, plastics exhibit high mechanical strengths even at elevated temperatures. This technique even makes it easy and cost-effective to produce parts of the engine compartment and drive train subject to heavy loads. Temperatures of up to 320 °C are possible even in continuous operation.

Reinforced polymers – for high-strength components

Components in a car have to be increasingly efficient. High strength with low weight is important for reduced fuel consumption. Compounds with fibre reinforcement, particularly our carbon-fibre reinforced LUVOCOM® compounds, offer precisely these properties – they are additionally electrically conductive. These compounds have been used for years in a range of applications within the automotive sector. Examples of applications for such components: engine-air management, transmissions, roof systems, steering and lighting.

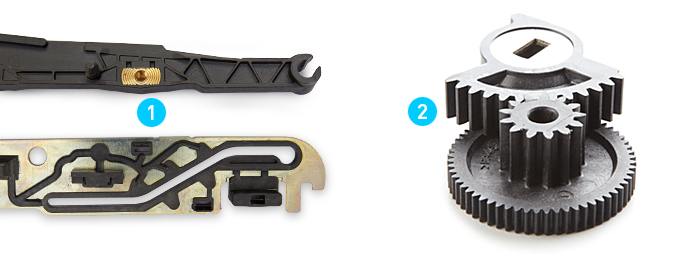

- Structural components in insert and outsert molding made of LUVOCOM® carbon fibre-reinforced and lubricantmodified

- Gear wheels made of LUVOCOM® - high-temperature resistant, reinforced with carbon fibres and lubricant-modified

With tribological optimization everything runs better

Many moving parts in a car are subject to high loads. During operation they must not wear and have to exhibit certain coefficients of friction. By adding lubricants and reinforcing materials such as PTFE, graphite, nanoadditives, carbon fibres and aramid, we significantly improve the tribological properties of thermoplastics. Tribologically adjusted LUVOCOM® compounds have deposits of lubricant, which saves on expensive and time-consuming steps of additional surface lubrication. These compounds are therefore not only suitable for self-lubricating bearings, but also for all multifunctional applications in which good slip characteristics and low wear are important. In tribological systems, the dry-running properties of these materials come to the fore and thus increase the safety level for designer and user alike.

Ball cup made of LUVOCOM® PBT, fibre reinforced, lubricant modified

Contact washers made of various LUVOCOM® compounds, fibre reinforced, lubricant modified

Electrically and thermally conductive – compounds for special requirements

Electrically conductive compounds are used in areas such as fuel management and infotainment. They prevent static charges in fuel-carrying components such as connectors or around the tank filler neck. In switches, electrical conductivity enables innovative solutions for applications such as capacitive systems.

Thermally conductive compounds prevent the overheating of components such as LED headlights, battery systems and other electrical components. This is where plastics offer the advantages over metals of lower weight, functional integration, corrosion resistance and often reduced costs. The thermal conductivity is adjusted according to the application.