Expertise in Mechanics

| Product highlights

|

Replacement of metals and composites (CFRP and GFRP)

Many applications call for materials with high strengths, while at the same time they have to be light – especially in the case of components subject to dynamic stress. Generally, properties such as low thermal expansion, high dimensional accuracy and long-term dimensional stability are additionally required.

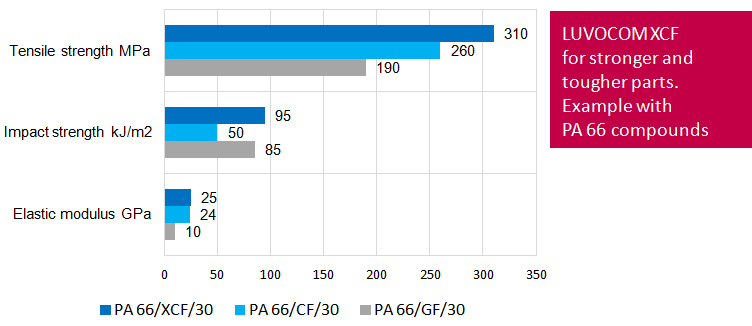

We meet these demands with specially fiber-reinforced compounds – particularly through the use of carbon-fiber reinforcement. The LUVOCOM XCF product line particularly stands out here.

Carbon-fiber reinforced thermoplastics

Typical applications for carbon fiber reinforced compounds are fast-moving components in the construction of machinery and apparatus – for example pump impellers, gear wheels, cams and connecting rods. In the automotive sector, these materials are used in air and exhaust management, in vacuum pumps, steering units as well as in the drive train. In aviation, the low weight and the stiffness of carbon fiber reinforced compounds open up countless opportunities in lightweight construction – examples include use for luggage racks and structural elements. As an alternative to aluminium in the fabrication of casings, carbon fiber reinforced materials have also proven their worth – and also for electromagnetic shielding (EMI).

LUVOCOM XCF - Top class products!

With the LUVOCOM XCF product line, LEHVOSS offers the world's leading thermoplastic carbon fiber compounds. LUVOCOM XCF provides tensile strengths of up to 425 MPa and tensile moduli of up to 52 GPa, as well as low thermal extension, improved thermal conductivity and high dimensional accuracy. As a result, it provides even greater scope for replacing metals and composite materials (CFRP and GFRP). LUVOCOM XCF compounds are used for components subject to high mechanical requirements. The motivation for this is the reduction in weight and costs. Another approach is to substitute plastics with short and long glass-fibre reinforcement in applications where additional weight savings are required. Examples of such applications are lifts with high-performance motors or electric drive systems. Additional weight savings of up to 30% are possible with LUVOCOM XCF compounds. Lower filler levels mean better processing characteristics and hence greater freedom in design. The materials can be processed in conventional injection moulding procedures without the need for special machines or techniques.