Expertise in Protection

| Product highlights

|

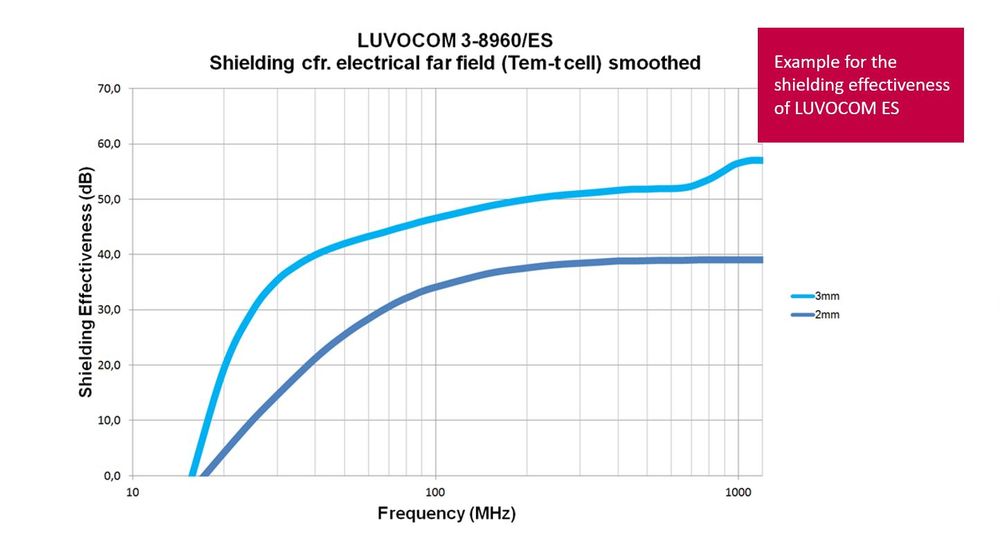

LUVOCOM ES – Electromagnetically shielding (EMI)

Being non-conductors (insulators), plastics are permeable to electromagnetic waves of up to approx. 100 GHz. A shielding effect is achieved by using conductive additives or coatings. The shielding effect is necessary in order to prevent electromagnetic emissions and hence rule out any influence on sensitive electronic devices - keyword electromagnetic compatibility (EMI)

LUVOCOM ES are shielding thermoplastic compounds. The special combination of additives results in a unique properties profile. It becomes possible to substitute conductive coatings or metal insets. This then leads to possibilities for cost savings. LUVOCOM ES compounds are ready-to-use, full compounds with rheology that has been optimized for ease of processing and injecting thin wall thicknesses. Segregation of the additives is ruled out. In comparison to polymer/masterbatch blends mixed in the injection moulding machine, this significantly lowers the risk of defective parts. LUVOCOM ES offers effective screening attenuation while its high electrical conductivity means that smaller contact surfaces are possible for the required electrical earthing.

The innovative additive system also enables attractive surfaces and tough materials. Flame-retardant compounds are also available.

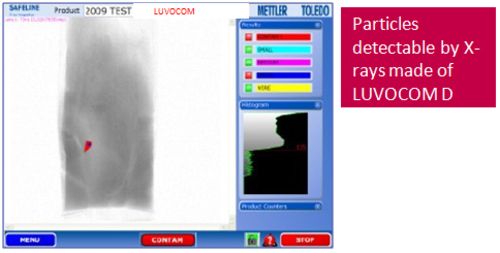

LUVOCOM D – Detectable compounds – so that nothing escapes you

To an ever-increasing extent, the food industry is using plastic for containers, moulds, housings, machinery parts, wipers, tools and other parts. These components do not always come into direct contact with the food but, when damaged, might contaminate the food in fragments of different sizes. Carelessness also enables tools to enter food. Consequently, any plastics deployed should be detectable. Conformity to the valid regulations for materials and articles in the food sector is also necessary, e.g. EU Regulation No. 10/2011/EEC. Migration limits in accordance with EN 1186 also have to be observed.

We offer made-to-measure solutions for these special requirements. The materials can generally be readily processed and are distinguished by attractive surfaces in the finished parts. Segregation of the additives is ruled out. Pigmentations are possible in numerous colour shades. In the food industry this also makes it possible to ensure a clear visual distinction from the foodstuffs being processed. Various shades of blue are frequently used because food rarely tends to exhibit this colour.

The range of polymers for LUVOCOM D is wide: from PE, PP, PA and POM, via PES, to PEEK, practically all thermoplastic materials can be supplied with this characteristic. To help in material selection, we also provide test rods and cards, which contain test specimens of various sizes made of different LUVOCOM D materials. This enables suitable formulations to be specified for the particular application.