Expertise in Tribology

| Product highlights

|

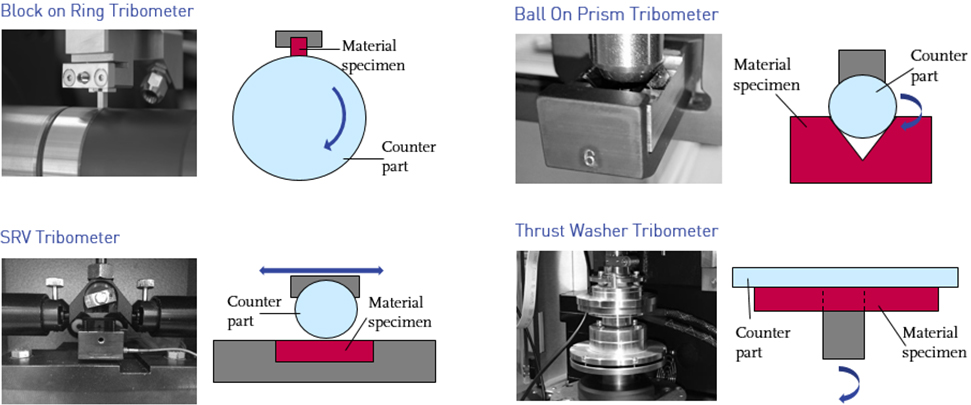

Materials tailored to the tribological system

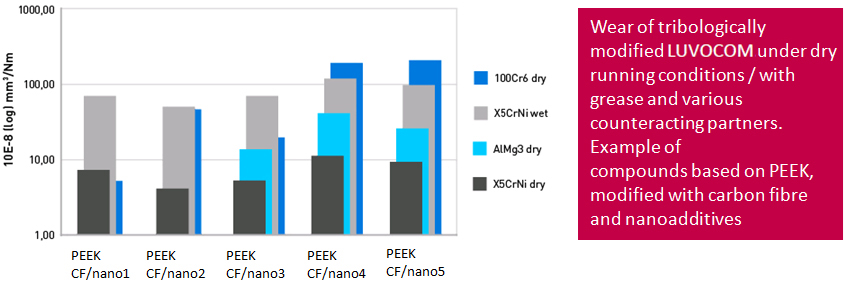

Tribologically optimized compounds for moving parts, such as friction bearings, gear wheels, rollers and sliders, in countless applications. Through the incorporation of lubricants and reinforcing materials, we improve the wear, friction and running-in characteristics of polymers and hence of the tribological system. The result is systems requiring little or no maintenance that function without additional lubrication. In lubricated assemblies, the dry-running properties of these materials come to the fore and thus increase the safety level for designer and user alike. Among the lubricants used are PTFE, graphite and silicone oil, while wear-reducing and reinforcing additives include fibers of carbon, glass, aramid and minerals as well as ceramic materials. In this field, we have long been relying on nanotechnology and are able to offer especially low-wear materials, also without PTFE.

In selecting the suitable material, we make use of our extensive know-how, our own test rigs and a wealth of experience. The various factors influencing the tribological system have to be taken into account. Examples include: material of the counteracting partner, pressure, speed, sequence of movements, time, temperature, surface design, influence of chemicals. The large number of tribological applications and the different requirements require tailor-made solutions. It is therefore also possible to set certain coefficients of friction, adapted to the tribological system.