LUVOCOM® P coating materials

Our coating powders are suitable for processing with electrostatic, tribo and vortex sintering procedures. Electrostatic coating with powder paints is of great economic significance. Ease of handling, the recovery of unused powders and the omission of solvents represent key advantages over wet painting.

Compared with conventional thermosetting powder paints, thermoplastic material can offer significant advantages in many applications. The functional powders of the LUVOCOM® P product group close the gap between simple polyamide coatings and expensive high-performance coating systems based on fluoropolymers.

Hard, black, non-stick: LUVOCOM® P 80-7858 B

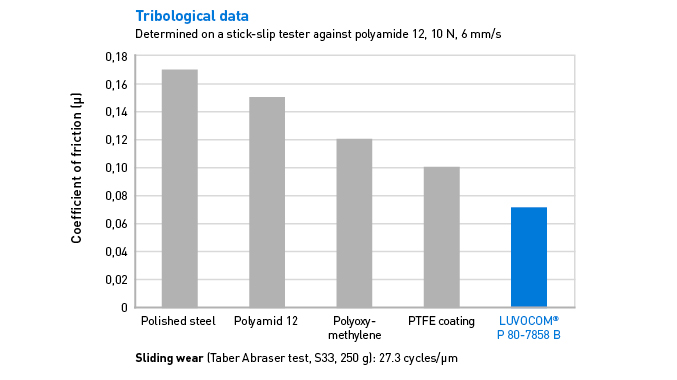

Exceptional wear resistance, excellent coefficients of sliding friction and high chemical resistance – LUVOCOM® P 80-7858 B offers clear benefits over conventional thermosetting antifriction lacquers. The material consists of polyoxymethylene (POM), modified with PTFE added to optimize its already very good antifriction properties. Special additives guarantee a deep black appearance despite the PTFE content.

LUVOCOM® P is also setting new standards in the field of environmental protection: unlike cross-linking antifriction paint systems, our thermoplastic coatings manage without problematic solvents when used as a powder layer. The material can be applied extremely economically by electrostatic means like a conventional powder paint (100 to 300 μm layer thickness).

A suitable primer system is employed in order to guarantee adhesion to metallic substrates, galvanized or phosphatized surfaces. This novel coating system of LUVOCOM® P opens up numerous applications, which include car manufacturing and mechanical or precision engineering.

Outstanding in sliding wear

LUVOCOM® in powder form for coatings.

The benefits at a glance:

- Processing with conventional electrostatic techniques

- Layer thickness of a few micrometres

- Excellent wear values

- Optimized gliding quality

- Application-tested

Our products offer you the possibility to coat metal components with LUVOCOM® materials. With conventional procedures for electrostatic powder coating, you can apply LUVOCOM® in layer thicknesses from 0.1 to 0.3 mm evenly on the metal surfaces. In this respect the partially crystalline polymers offer considerably higher wear resistance than thermosetting lacquers.

Corrosion resistance is also improved. We modify the polymers in line with your wishes in order to adjust functionalities. LUVOCOM® P 80-7858 B on the basis of polyoxymethylene (POM), for example, is equipped with lubricant modification and displays excellent slip characteristics and frictional properties. The coating is therefore used on various kinematic components in the automotive industry.

If you do not have your own powder coating capacities, we will be glad to put you in touch with suitable service providers who already use our materials.

Powder-coating materials

| LUVOCOM® P | Material | Application |

|---|---|---|

| 80-7858 B | POM lubricant-modified | Wear-resistant antifriction coating |

| 1850-8815 | PBT lubricant-modified | Wear-resistant antifriction coating |

| 96-7865 | PE rheologically optimized | Heavy-duty corrosion protection |

Individual powder solutions

The production of plastic powders is costly. Industrial plastics are ground mechanically at cryogenic temperatures. Intermolecular bonding forces or electrostatic charges on the small lightweight particles are so dominant as to obstruct their further processing and handling. Special additives thus guarantee their free-flowing properties. The absence of pressure during processing demands a modified melt rheology compared with injection moulding; the polymeric powders are intended to undergo sintering to form a thin, dense film but preferably with their full molecular weight in order to retain their mechanical properties. Finally, surface tensions have to be adjusted to allow the particles to agglomerate in the heat. We master these processes that make our LUVOCOM® P products into specialities.

Do you have specific requirements of thermoplastics in powder form? We will be only too pleased do develop tailor-made products for you and provide you with support on your way to series production.